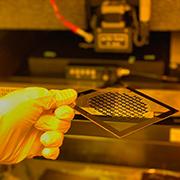

Mask Aligner MA6 GEN4

Q: What are the primary applications of the SUSS MicroTec MA6 Gen4 at the TAU Nano Center?

A: The SUSS MA6 Gen4 is a high-resolution photolithography tool primarily used for micro-patterning in the fabrication of MEMS, optoelectronics, and microfluidic devices. It is designed for precise mask-to-wafer alignment and exposure, supporting both research-scale and production projects.

Q: What is the alignment accuracy of the MA6 Gen4 mask aligner?

A: The MA6 Gen4 offers exceptional precision with sub-micron alignment accuracy. It features advanced Top Side Alignment (TSA) and Back Side Alignment (BSA) capabilities, making it ideal for double-sided lithography and complex multi-layer device fabrication.

Q: What wafer sizes and substrates are compatible with the MA6 Gen4?

A: Our facility’s MA6 Gen4 is highly versatile, supporting a wide range of substrates from small pieces and 2-inch wafers up to 150mm (6-inch) wafers. It can handle various materials, including Silicon, Glass, and III-V compounds, with specialized chucks for different thicknesses.

Q: Which exposure modes does the SUSS MA6 Gen4 support?

A: The system supports multiple exposure modes to optimize resolution and throughput, including Proximity, Soft Contact, Hard Contact, and Vacuum Contact modes. This allows users to achieve high-resolution patterns while protecting delicate masks and substrates.

Q: Is the MA6 Gen4 available for independent use by external industrial partners?

A: Yes. The Tel Aviv University Nano Center provides access to the MA6 Gen4 for both academic researchers and industrial users. External partners can choose between independent tool operation (following a comprehensive certification process) or professional service provided by our expert lithography engineers.