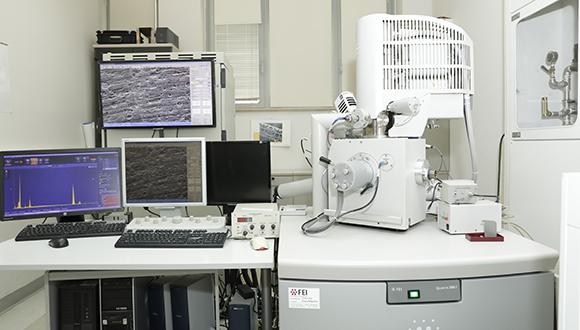

Environmental Scanning Electron Microscope (ESEM).

Manufacturer and model:

ThermoFisher, Quanta 200 FEG ESEM.

Description:

The Quanta 200 FEG Environmental Scanning Electron Microscope (ESEM) uses a field-emission gun (FEG) electron source in an exceptionally high chamber pressure environment. The Quanta 200 FEG can be switched between three vacuum modes: high vacuum, low vacuum and environmental/wet modes. It thus enables investigation of conductive, non-conductive and high-vacuum incompatible materials including wet samples.

The laboratory main advantages:

-

Nanometer resolution in both high vacuum and wet modes.

-

Real "wet" mode (100% humidity in the specimen chamber) and thus a possibility to examine specimens with a high vapor pressure in the chamber.

-

Large number of detectors and attachments.

-

Ease of operation of basic SEM modes.

The system has specific attachments:

- EBSD-EDS Oxford integrated analytical system - the electron backscattered diffraction (EBSD) detector is NORDLYS II of Oxford with integrated forescatter detectors and Aztec processing software. The EBSD detector provides texture information by performing phase identification and orientation mapping. The EBSD system is integrated with energy dispersive spectroscopy (EDS) system. The EDS uses X-Max SDD Oxford detector of 127eV resolution (at Mn) with element analysis down to Boron.

-

Kammarath & Weiss Tensile system - in-situ materials testing and continuous dynamic studies with micro-structural information are provided by the tensile stage in ESEM. Ordinary load cell of 200N. The microprocessor provides pre-selected displacement speeds over a range of 0.1µm/s to 20µm/s. The module can be operated from a microprocessor/PC combination, which displays the applied force and the actual elongation.

-

Zyvex S100 Nanomanipulator - the Zyvex S100 system is a manipulation and testing tool. The system consists of nanomanipulator, a control cabinet housing the PC and electronics, a joystick and window based control system. The S100 features up to four positioners. It provides in- situ mechanical and electrical characterization of micro and nano device structures. Equipment for SEM coating: Polaron E6500 evaporator & Quorum Q150T S Sputter Coater.